At Devanshi Electronics Pvt. Ltd., we offer high-performance Sprue Pickers designed for injection molding machines. These robotic devices are built to quickly and efficiently remove sprues, runners, or small molded parts from the mold area, ensuring smooth production and minimizing downtime.

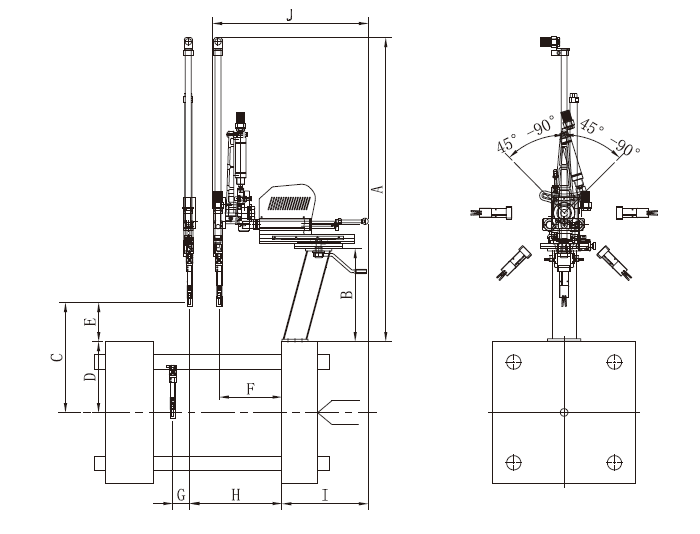

DH-P68 sprue picker robotic arm is a compact designed cylinder cushion arm with multiprogramming operating system. It’s designed for the picking of small items and sprue from the injection molding machine.

Advantages of using sprue picker

1. Very high throughput without the human involvement

2. Gives high accuracy and efficiency as compared to manual process

3. Reduces Cycle time

4. Ensures repeatability of the cycle time hence improves final product quality

5. Very fast ROI

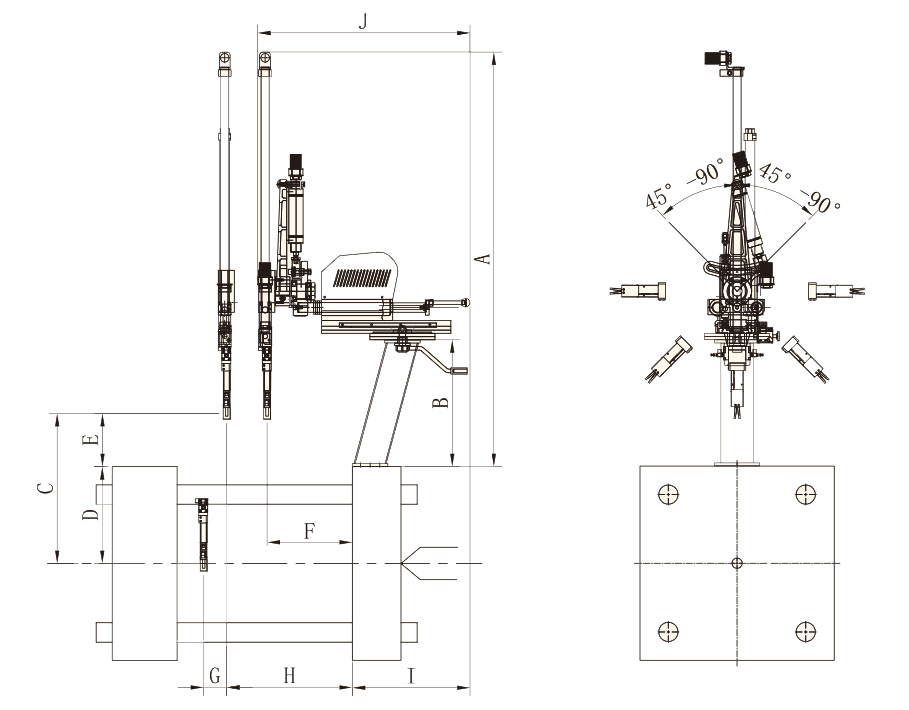

DH-710 sprue picker robot arm is a compact design servo based arm with multiprogramming operating system. It’s designed for the picking of small items and sprue from the injection molding automation system.

Advantages of using sprue picker

• Very high throughput without the human involvement

•

Gives high accuracy and efficiency as compared to manual process

•

Reduces Cycle time

•

Ensures repeatability of the cycle time hence improves final product quality

•

Very fast ROI

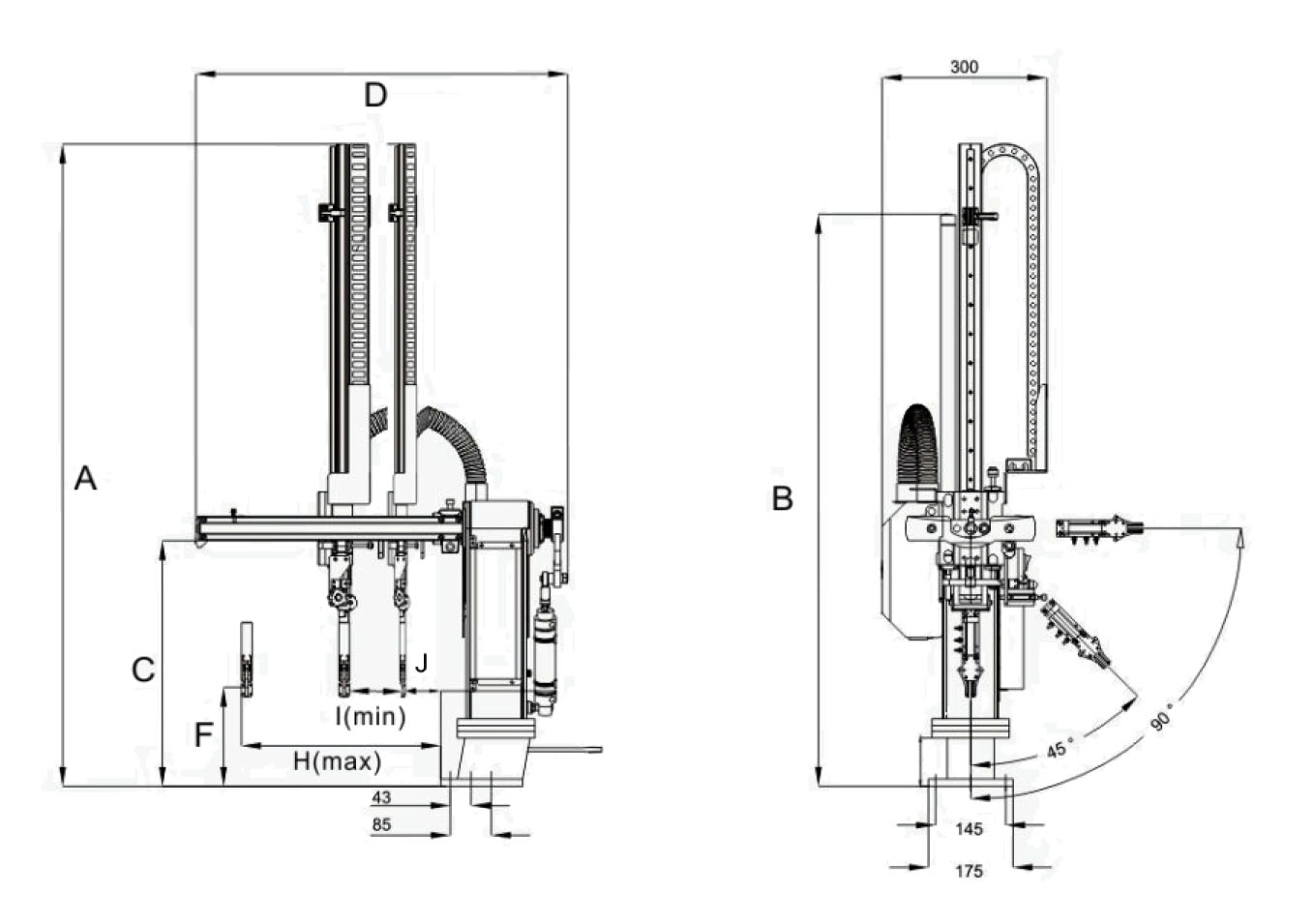

DH-P18 / DH-P28 sprue picker robot arm is a compact design cylinder cushion arm with multiprogramming operating system. It’s designed for the picking of small items and sprue from the injection molding automation system.

DH-P38 sprue picker robot arm for vertical automation molding machine with multiprogramming operating system. It’s designed for the picking of small items and sprue in from the injection molding automation system.

DH-P38 sprue picker robot arm for vertical automation molding machine with multiprogramming operating system. It’s designed for the picking of small items and sprue in from the injection molding automation system.

Advantages of using sprue picker

1. Very high throughput without the human involvement

2. Gives high accuracy and efficiency as compared to manual process

3. Reduces Cycle time

4. Ensures repeatability of the cycle time hence improves final product quality

5. Very fast ROI

©Copyright 2025 Devanshi Electronics Pvt Ltd All Rights Reserved. (terms Of Use) Developed And Managed By SME Business Services Ltd